If you’re a fan of the Aurora 88, by which I mean the original version with a semi-hooded nib, you might have encountered one or two 88s that would have been gorgeous pens if their pistons hadn’t died. It’s a sad fact that the material Aurora used doesn’t hold up against the ravages of ordinary moderately acidic inks; it becomes brittle and eventually cracks apart under stress. The point at which this happens is the end of the piston, and the failure results in the disintegration of the threads onto which the hard rubber cap nut screws. Soon the hard rubber nut can no longer get a purchase. The piston head comes apart, and the pen won’t fill.

Absent a replacement part, what do you do? Here’s what I did today for a client’s 88P. First, the pen with its piston in pieces:

The left end of the piston shaft, which is badly stained by ink, is also only a stub, no longer able to hold the nut in place.

The first step is to machine the dead material away. It happens that the shank diameter of the threaded part is 0.190”, which is most certainly close enough to 3/16” (0.1875”) for government work. I machined the stub’s diameter down to fit the inside of hobby-shop 3/16” polystyrene tubing, and I cut the stub off to a length just slightly shorter than the combined thickness of the two seals and their spacer. Next I cut a piece of the tubing to the length I’d left on the piston.

Slipping the tubing sleeve over the end of the piston, I then drilled and tapped the end of the piston for a 2-56 screw. I put the sleeve in place first to take advantage of its mechanical strength, so that the relatively brittle piston wouldn’t shatter under the stress of drilling and tapping.

Here the piston is ready for its new end cap.

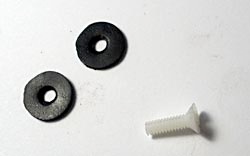

For an end cap, I decided on more polystyrene, this time two punchings from 1/32“ sheet. For this I set up my arbor press with one of Francis Goossens’ excellent punches for making plunger-filler seals.

The punchings came out of the press with a conical shape, but it was easy to press them flat. I then fused them together to make a disc 1/16“ thick, and a little work with a buff-stick and an X-acto knife cleaned up the edges and countersank one face for the head of my screw. Shown here are the two washers before fusing, with the 5/16“-long 2-56 flat-head screw.

Next, I installed the piston seals and their spacer into place, applied some shellac to the screw threads to prevent leakage through the center of the piston, and completed the assembly.

It turned out that the original seals were dead, so I had to disassemble the unit once more. To provide a good seal, I made a custom-size washer of plunger-filler gasket material that I could use in place of the original spacer. Putting it all back together left me — and my client — with a working Aurora 88P. This is an official Good Thing, and it was fun, too!